|

|

|

|||||

|

|

|

|

|||

|

|

|||||

Pneumatic Temperature Controllers

|

Specialty

Items

|

|

|

|

How are they

used |

Basic

Information |

|

|

|

DRIP, TRACER: The TD600

Thermodynamic Steam Trap is commonly used as a drip trap on steam

mains and steam supply lines. These traps can be used on tracing

applications; however, thermostatic traps are normally recommended for this

service. Ideal for outdoor applications that are subject to freezing and for

superheated steam conditions. |

Model: TD600 |

|

|

DRIP, TRACER: The TD600S

Thermodynamic Steam Trap is commonly used as a drip trap on steam

mains and steam supply lines. Supplied with integral strainer and optional

blowdown valve to protect the trap from contamination. These traps can be

used on tracing applications; however, thermostatic traps are normally

recommended for this service. Ideal for outdoor applications that are subject

to freezing and for superheated steam conditions. |

Model: TD600S |

|

|

DRIP, TRACER: The TD700S

Thermodynamic Steam Trap is commonly used as a drip trap on steam

mains and steam supply lines. These traps are used on tracing applications;

however, thermostatic traps are normally recommended for this service.

Supplied with an integral strainer and optional blowdown valve to protect the

trap from contamination. The internal working mechanism of the WD700S can be

completely replaced while the trap body remains in line. Ideal for outdoor

applications that are subject to freezing and for superheated steam

conditions. |

Model: TD700S |

|

|

DRIP: The TD900S/TD900LS

Thermodynamic Steam Trap is primarily used as a drip trap on high

pressure steam mains and steam supply lines. Ideal for outdoor applications

that are subject to freezing and for superheated steam conditions. |

Model: TD900S |

|

|

DRIP, TRACER: The TD3600 Thermodynamic Steam Trap is commonly used as a drip

trap on high-pressure steam mains and steam supply lines. Supplied with an

integral strainer to protect the trap from contamination. The internal

working mechanism of the TD3600 can be completely replaced while the trap

body remains in line. Ideal for outdoor applications that are subject to

freezing and for superheated steam conditions |

Model: TD3600 |

|

How are they

used |

Basic

Information |

|

|

|

DRIP,

TRACER: The WT1000

Thermostatic Steam Trap was specifically designed for drip and

tracing applications as well as an air vent for heat exchangers. Like all

thermostatic traps, the WT1000 is small, light, and has excellent air

handling capabilities. The discharging of air on start-up allows steam to

enter the system more quickly. |

Model: WT1000 |

|

|

DRIP, TRACER, PROCESS: The WT2000 Thermostatic Steam Trap is used for drip, tracing, and process applications. Their compact size, all stainless steel construction, excellent air handling capabilities, and the ability to operate over a wide pressure range make them a good choice for most applications. They can also be used as an air vent on heat exchangers. Thermostatic traps are far superior to bucket traps and thermodynamic traps in their ability to remove air from the system. The discharging of air on start up allows steam to enter the system more quickly |

Model: WT2000 |

|

WT2500 |

DRIP, TRACER,

PROCESS: The WT2500

Thermostatic Steam Trap is used for drip, tracing and process

applications. Their compact size, excellent air handling capability and wide

operating pressure range make them a great choice for most applications.

Thermostatic traps are far superior to bucket traps and thermodynamic disc

traps in their ability to remove air from the system. |

Model: WT2500 |

|

WT3000 |

PROCESS: The WT3000 Thermostatic

Steam Trap is used for industrial process applications. Their

compact size, all stainless steel construction,

excellent air handling capability and wide operating pressure range make them

a great choice for most process applications. Thermostatic traps are far

superior to bucket traps and thermodynamic disc traps in their ability to

remove air from the system. |

Model: WT3000 |

|

|

PROCESS: The WT4000 Thermostatic Steam Trap is used for industrial process applications. Their compact size, all stainless steel construction, excellent air handling capability and wide operating pressure range make them a great choice for most process applications. Thermostatic traps are far superior to bucket traps and thermodynamic disc traps in their ability to remove air from the system. |

Model: WT4000 |

|

WT5000 |

TRACER: The WT5000 Series Bimetal Steam Trap is used in steam tracing applications (process lines, instrumentation and winterization, general steam jacketing) and small process applications where accurate control of condensate discharge temperature is required to utilize the sensible heat of the condensate. |

Model: WT5000 |

|

|

TA25B,TA125,TS25B,TS125 Thermostatic Steam Trap are predominantly used in

the HVAC industry. They are referred to as radiator traps because the

quick-disconnect right angle connection is found on most radiator

installations. Their excellent air handling capabilities, compact size, and

economical cost make them a great choice for air vents on heat exchangers or

for steam trap applications on OEM equipment. |

Model: TA25B, TA125 & TS25B, TS125 |

|

|

|

|

|

How are they used |

Basic

Information |

|

|

DRIP, PROCESS: The FT Series Float & Thermostatic Steam Traps are used for HVAC and light industrial process applications, and can be applied to unit heaters, water heaters, pressing machines, heat exchangers, and coils. These traps have excellent air removal capability making them an excellent choice for HVAC and process applications requiring quick start-up. |

Model: FT |

|

|

FT600 & FT601 |

PROCESS The FT600 & FT601 Series High Pressure Float & Thermostatic Steam Traps are primarily used on industrial process applications. The excellent air handling capabilities of float and thermostatic traps make them a better choice than bucket traps for applications requiring quick system start-up. These traps have in-line pipe connections. Used in chemical plants and petrochemical refineries on reboilers, heat exchangers, and other critical process applications. Model FT601 is identical to FT600 except body material is 316 SS. |

Model: FT600 & FT601 |

|

PROCESS: The FTE & FTES Series Float & Thermostatic Steam Traps are used in HVAC and on industrial process equipment with very high load requirements. These high capacity steam traps are typically used on reboilers, absorption chillers, large air handling coils, large heat exchangers, and other large process equipment. |

Model: FTE & FTES |

|

DRIP, PROCESS: The FTT Series Float & Thermostatic Steam Traps are used in drip and process applications, industrial and HVAC process equipment. The excellent air handling capabilities of float and thermostatic traps make them a better choice than bucket traps for applications requiring quick system start-up. These traps have in-line pipe connections. Used on unit heaters, textile machines, heat exchangers, and other medium sized process equipment. |

Model: FTT |

|

|

WFT |

PROCESS: The WFT Series

Float & Thermostatic Steam Traps are used for HVAC and

industrial process applications. The excellent air handling capabilities of

these traps make them a better choice than bucket traps for applications

requiring quick start-up. Used on unit heaters, textile machines, heat

exchangers, and other process equipment. |

Model: WFT |

|

|

|

|

|

How are they

used |

Basic

Information |

|

|

|

DRIP, TRACER: The WSIB Inverted Bucket Trapis primarily used in drip and tracer applications. Inverted bucket traps can handle superheated steam when a check valve is used. These traps are also used on unit heaters, laundry equipment, and other small process equipment where slow start-up due to poor air handling capability can be tolerated |

Model: WSIB & WSIBH |

|

|

DRIP, TRACER, PROCESS: The IB Series Inverted Bucket Traps are available in several sizes and capacity ranges. Inverted bucket traps can handle superheated steam when a check valve is used. The smaller traps are primarily used in drip and tracer applications. These traps are also used on unit heaters, laundry equipment, and other process equipment where slow start-up due to poor air handling capability can be tolerated. Larger sizes are used on process equipment; however, since bucket traps have limited air handling capability, F&T traps are the preferred choice. |

Model: IB Series |

|

How the are used |

Basic

Information |

|

|

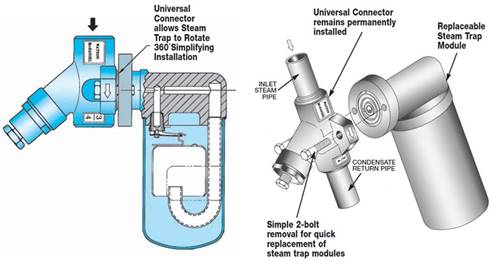

The UC450 Series QUICK-CHANGE

Universal Trap-Connector System with multiple choices for trap modules

and multiple choices for connectors are used in steam systems where a

simplified and economical maintenance program of steam traps is desired.

These Universal Style quick replacement steam traps can be used on steam

supply lines as well as for tracing and small process applications. They are

commonly used in chemical plants, petrochemical refineries, paper mills and

other industrial facilities. |

The All Stainless Steel Universal Style Steam Traps feature a permanent

installation of the Universal Connector with a 2-bolt mounting arrangement

for the Universal Steam Trap Module, allowing the Steam Trap to be removed

and replaced in minutes: • Steam trap is replaced without having to unthread

piping • By removing only 2 bolts with a socket or open-end wrench • Trap

module can swivel 360º on the universal connector allowing proper orientation |

|

|

Universal

Connectors |

How the are used |

Basic

Information |

|

|

Model UC450 Universal Connector is a basic

connector with no strainer. |

Model: UC450 |

|

|

Model UC450S Universal Connector comes with

an integral strainer. |

Model: UC450S |

|

|

Model UC450SBR Universal Connector comes with

an integral strainer and blowdown valve. |

Model: UC450SBR |

|

|

Model W450S-LR Universal Connector comes with

an integral strainer and is used for Left-To-Right flow

directions. |

Body Material: Stainless Steel |

|

|

Model W450S-RL Universal Connector comes with

an integral strainer and is used

for Right-To-Left flow directions. |

Model: WU450S-RL |

|

|

Model W450SB-LR Universal Connector comes with

an integral strainer and blowdown valve, and is used for Left-To-Right flow

directions. |

Model: WU450SB-LR |

|

|

Model W450SB-RL Universal

Connector comes with an integral strainer and blowdown valve, and is used for Right-To-Left flow

directions. |

Model: WU450SB-RL |

|

|

|

|

|

Universal Steam

Trap Modules |

How the are used |

Basic

Information |

|

|

DRIP, TRACER: The USIB450 Inverted Bucket

Steam Trap Module,

mounted to a universal connector, is typically used for drip and tracing

applications. Also used on process equipment with light loads and where air

removal is not critical. The WSIB450 trap module mounts to any universal

connector. |

Model: USIB450 |

|

|

PROCESS, DRIP: The UFT450 Float &

Thermostatic Trap Module mounted to a universal connector, is

typically used on process equipment that generate light condensate loads and

require excellent air handling capabilities. These low capacity float &

thermostatic trap modules can also be used in drip service on steam mains,

tracer systems and steam supply lines. The WFT450 trap module mounts to any

universal connector. |

Model: UFT450 |

|

|

DRIP, TRACER: The WD450 "Top Mount"

Thermodynamic Steam Trap Module mounted to a universal

connector can be used anywhere conventional thermodynamic steam traps are

used. Used on drip, tracing and light process applications where removal of

air is not critical. The WD450 trap module mounts to any Universal Connector.

The WD450 is recommended for horizontal piping only so that cap can be

oriented upwards, as shown. |

Model: WD450 |

|

|

DRIP, TRACER: The WD450SM "Side Mount" Thermodynamic Steam Trap Module mounted to a universal connector can be

used anywhere conventional thermodynamic steam traps are used. Used on drip,

tracing and light process applications where removal of air is not critical.

The WD450SM trap module mounts to any Universal Connector. |

Model: WD450SM |

|

|

DRIP, TRACER: The WD600LSM-HP "Side

Mount" Thermodynamic Steam Trap Modulemounted to a universal connector

can be used anywhere conventional thermodynamic steam traps are used. Used on

drip, tracing and light process applications where removal of air is not

critical. The WD600LSM-HP trap module mounts to any Universal Connector. |

Model: WD600LSM-HP |

|

Submittal Download |

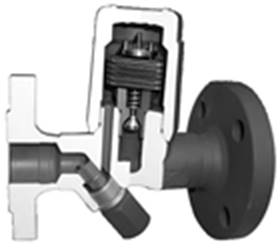

DRIP, TRACER, PROCESS: The WT450 Thermostatic

Steam Trap Module mounted

on a universal connector can be used anywhere conventional thermostatic steam

traps are used. Used on drip, tracing and light process applications. The

WT450 trap module mounts to any universal connector. |

Model: WT450 |

|

|

The UB450 Series Bi-Metallic

Steam Trap Moduleis used in steam tracing applications

(process lines, instrumentation and winterization, general steam jacketing) and

small process applications where accurate control of condensate discharge

temperature is required to provide maximum usage of energy |

Model: UB450 |

|

|

|

|

|

How the are used |

Basic Information |

|

|

FDA300 |

DRIP, PROCESS: The FDA300 Series Thermostatic Steam Traps are used on clean steam

applications, and for condensate drainage on CIP/SIP systems and various

process vessels. |

Model: FDA300 |

|

FDA400 |

DRIP, PROCESS: The FDA400 Series Thermostatic Steam Traps are used on clean steam

applications as drip traps on piping runs as well as drainage for CIP/SIP

systems and various process vessels. The FDA400 Series allows for a 90°

connection on either the inlet or outlet capable of 360° orientation. |

Model: FDA400 |

|

FDA500 |

DRIP, PROCESS: The FDA500 Series Thermostatic Steam Traps are used on clean steam

applications as drip traps on piping runs as well as drainage for CIP/SIP

systems and various process vessels. |

Model: FDA500 |

|

FDA600 |

DRIP, PROCESS: The FDA600 Series

Thermostatic Steam Traps are used on clean steam applications as drip

traps on piping runs as well as drainage for CIP/SIP systems and various

process vessels. |

Model: FDA600 |

|

|

DRIP, PROCESS: The FDA800 Series

Thermodynamic Clean Steam Traps are used in sanitary systems as drip

traps on steam mains as well as for drainage on various process vessels such

as separators and filters. |

Model: FDA800 |

|

|

|

|

|

|

|

|

|

How the are used |

Basic Information |

|

|

DRIP, TRACER, PROCESS: The WPN Series Bi-Metallic

Steam Traps are

use in steam tracing, steam main drips and non-critical process equipment.

They can be used in outdoor applications that are subject to freezing.

Bi-Metallic traps will back up some condensate into the system and should

only be used when this condition is permissible. |

Model: WPN Series |